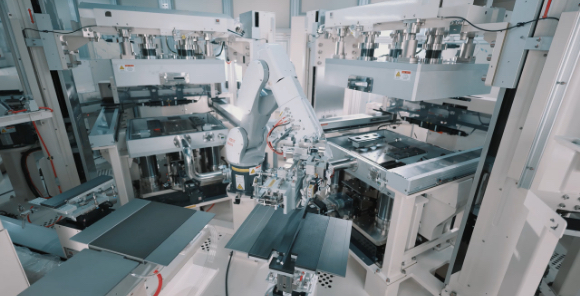

Material Handling Systems department provides innovative logistics systems by integrating industry-leading manufacturing capabilities with smart factory technologies.

SFA’s Material Handling Systems Department first started the logistics automation business in Korea. The department has innovative technologies and extensive know-how which enable the company to successfully provide a total solution including analysis, system engineering, design, equipment production, construction and after-sales service.

Based on its expertise coming from executing the largest number of material handling projects in Korea, SFA successfully entered diverse distribution & logistics markets including markets specialized in handling materials under special environment(GMP, HACCP, hazardous materials, refrigeration/cooling, electric/electronic goods, heavy goods, etc.) while complying with supply chain management(SCM) regulations. Based on its technological expertise and manufacturing capabilities, the company was able to diversify a product mix which handles logistics in manufacturing secondary batteries, OLED/LCD, semiconductor, panel glasses, film, and etc.

SFA is committed to developing technologies for logistics systems & manufacturing equipment that meet customers’ needs in diverse industries and pioneering a new paradigm of providing total solutions using SFA’s smart factory solutions which are ‘NEO AI’ and ‘NEO Platform’.

SFA is dedicated to providing key manufacturing equipment and high-productivity equipment to high-tech industries.

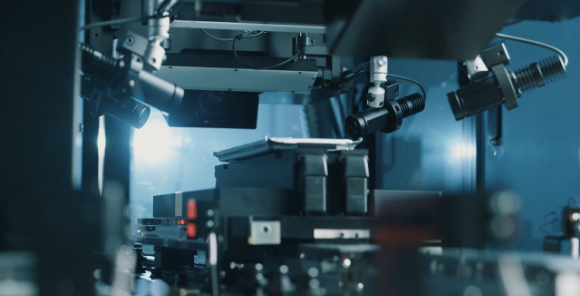

Process & Precision Equipment department is leading the localization of key equipment for high-tech industries such as display(OLED, Micro LED, and etc.) and secondary battery by combining deep expertise in equipment with smart technologies.

Based on its expertise in vacuum equipment and automation, PPE department is leading the development of technologies such as evaporation/encapsulation/vacuum logistics for large-sized OLED. Having succeeded in developing Korea’s first solution process equipment used in pattern making for semiconductor and display, the department focuses on expanding the front-end equipment business.

In addition, PPE department successfully developed and commercialized laminators for flexible OLED, laser ablation equipment, AI AOI system, In-line 3D CT inspectors, and so on. PPE department is committed to providing customers with competitive edges in their businesses by offering them its extensive experience, technical expertise, and smart factory solutions.