Based on its expertise from having supplied clean logistics in all the process of semiconductor production(wafer production, front-end, EDS, back-end) and the largest manufacturing infrastructure in the industry, SFA executes large-scale turnkey projects and has a global customer service system for customers in Korea, Taiwan, Singapore, China, and so on.

Besides, SFA is actively engaging in the application of its own smart factory solutions such as NEO AI & NEO Platform to various equipment, and development/commercialization of Predictive Maintenance(PdM) system.

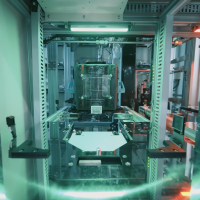

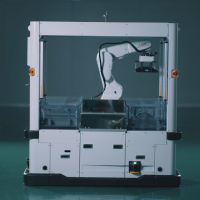

SFA delivers various types of clean logistics & test equipment for front-end/back-end/test processes in manufacturing semiconductors. SFA is aggressively expanding the application of its own AI, Route, and Predictive Maintenance(PdM).